Ever wonder why that seven-year-old dishwasher repair quote made your jaw drop, or why your washing machine seems to break down right when it’s too old for warranty but too new to justify replacing? The cruel reality is that appliances aged 7 years hit homeowners with the worst possible combination – they’re past their protective coverage but nowhere near ready for the scrapyard.

Picture this scenario that plays out in Maple Ridge homes every week: Your trusty refrigerator that’s been faithfully keeping your groceries cold for seven solid years suddenly starts making strange noises and struggling to maintain temperature. You call for a repair estimate, and the technician delivers the dreaded news – a compressor replacement will cost $650, plus diagnostic fees. Meanwhile, a comparable new refrigerator costs $1,400, making the repair seem reasonable at first glance. But here’s where the math gets tricky and expensive.

At seven years old, your refrigerator has already lived through roughly 58% of its expected 12-year lifespan. That $650 repair represents nearly half the cost of replacement, but you’re only getting about 42% of the appliance’s total useful life in return. Add in the reality that this aging appliance is consuming 20% more energy than modern models, and suddenly that “reasonable” repair starts looking like financial quicksand. This is the seven-year appliance trap that catches thousands of homeowners off guard.

Living in Maple Ridge adds another layer of complexity to appliance decision-making. Our coastal humidity accelerates internal corrosion, while moderate-to-hard water creates scale buildup that shortens component life by 2-3 years compared to drier regions. The Fraser Valley’s service market also means higher diagnostic fees and longer wait times than Metro Vancouver, making every repair decision more consequential for both your wallet and daily routine.

Key Outtakes:

- Seven-year-old appliances occupy the worst cost-to-value position because they’re beyond warranty protection but not old enough to justify automatic replacement

- Major component failures like compressors, control boards, and motors typically occur between years 6-8, with repair costs ranging $300-800 depending on appliance type

- The traditional 50% repair rule should be modified to 35-40% for seven-year-old appliances since they’ve consumed most of their expected lifespan

- Maple Ridge’s coastal climate and hard water reduce appliance lifespans by 25-30% compared to interior regions, making the seven-year mark even more critical

- Energy efficiency losses of 15-25% in aging appliances create hidden costs of $100-200 annually, compounding the repair-versus-replace decision

The Seven-Year Appliance Paradox: Why This Age Hits Hardest

The seven-year mark represents a perfect storm of appliance economics that creates maximum financial pain for homeowners. This isn’t coincidental – it’s the predictable result of how modern appliances are designed, warrantied, and expected to fail. Understanding why this age hits hardest requires examining the intersection of warranty coverage, component engineering, and energy efficiency degradation.

Every new appliance comes with manufacturer warranty protection that typically covers one year for parts and labor, with some premium brands extending to two or three years. Extended warranties purchased at retail add another 2-4 years of coverage, meaning most protection expires between years 3-7. By year seven, your appliance carries zero manufacturer liability for repairs, leaving you to absorb 100% of any failure costs. This protection vacuum occurs precisely when expensive components are most likely to fail.

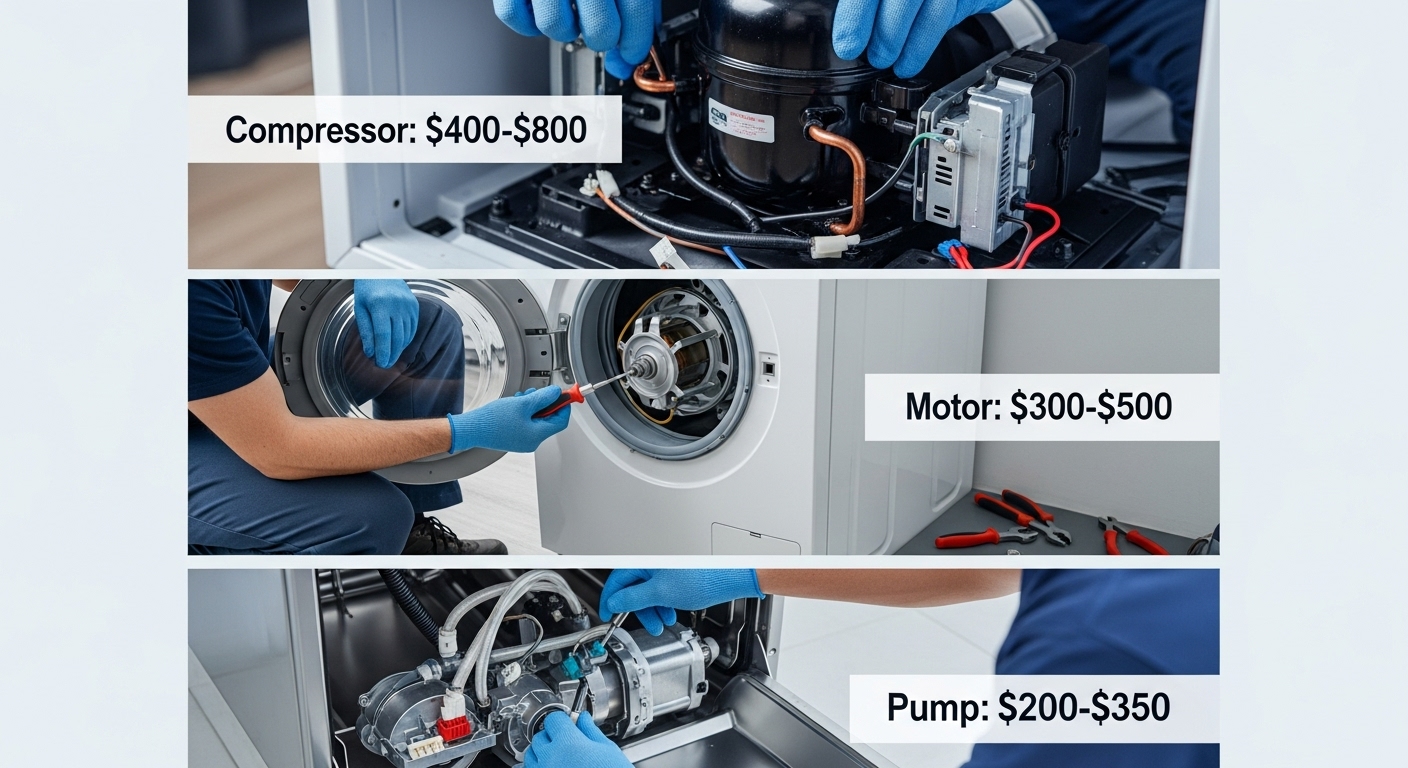

Modern appliances contain 15-20 circuit boards and complex mechanical systems engineered for roughly 8,000-12,000 operating hours. For daily-use appliances like refrigerators and dishwashers, this translates to 6-8 years before first major component failure becomes statistically probable. The most expensive components – compressors averaging $562 in repair costs, control boards running $250-450, and motor assemblies costing $300-500 – cluster their failures around the seven-year mark like a coordinated assault on your household budget.

Even appliances that appear to function normally at seven years are operating at significantly reduced efficiency. Refrigerator compressors cycle more frequently due to degraded seals and worn components, increasing energy consumption by 15-25%. Washing machine motors work harder due to bearing wear, using 10-20% more electricity per load. This efficiency loss compounds over the remaining lifespan, representing $500-1,200 in excess energy costs that homeowners rarely factor into their repair decisions.

Parts availability creates additional pricing pressure at the seven-year mark. Manufacturers begin discontinuing components for models 7-10 years old, creating scarcity that drives up costs for remaining inventory. While parts aren’t yet impossible to find, they’re becoming rare enough to command premium pricing. This supply constraint hits just as demand peaks due to the natural failure curve, creating a double squeeze on repair costs.

Repair Cost Reality: What Seven-Year-Old Appliances Actually Cost to Fix

Understanding specific repair costs by appliance type provides the foundation for making informed decisions about whether to repair or replace seven-year-old units. These costs have risen significantly in recent years due to increased component complexity and supply chain challenges, making the repair-versus-replace calculation more critical than ever.

Refrigerators consistently rank as the most expensive appliances to repair at any age, with seven-year-old models typically requiring repairs in the $400-800 range. The most common failures involve compressor issues affecting 20% of repairs at an average cost of $500-650, control board malfunctions representing 18% of repairs costing $200-400, and evaporator fan motor replacements accounting for 15% of repairs at $300-450. These major component failures can cost anywhere from $200 for minor fixes to over $1,300 for complex sealed system problems. With median new refrigerator costs around $1,400 plus installation, a $600 compressor repair represents 35-39% of replacement cost – within traditional guidelines but questionable given the appliance’s advanced age.

Washing machines and dryers present the most difficult decision matrix at seven years, with repair costs ranging $125-450 for washers and $100-450 for dryers. Transmission failures in seven-year-old washers can cost $300-500, representing 40-60% of replacement cost for mid-range units. Front-load washers face particularly expensive bearing replacements that often coincide with seal issues, creating comprehensive repair bills of $600-800. Dryer repairs center on heating elements ($100-150), motor replacements ($300-450), and control board failures ($200-350).

Dishwashers offer the clearest decision framework at seven years due to their relatively short 9-12 year lifespan and moderate replacement costs of $600-1,200. Common seven-year failures include pump assembly replacements costing $200-350 and control board failures at $200-300. When dishwashers older than 8 years face repairs exceeding $300, replacement typically makes more financial sense. Modern dishwashers also offer significant efficiency improvements, using 30-40% less water and 20-30% less energy than seven-year-old equivalents.

Ovens and ranges maintain different economics at seven years due to their extended 15-20 year lifespans. Repair costs typically range $200-500, with heating element replacements at $100-200 remaining cost-effective even for seven-year-old units. Gas ranges may require slightly higher repair investments due to safety regulations and specialized expertise, but their longer expected life makes repairs worthwhile in most scenarios.

The Hidden Mathematics of Appliance Repair Decisions

The visible repair estimate represents only 60-70% of the true cost when all factors are included. Professional diagnostic fees run $75-100 even if you decide against repairs, while service call charges add another $50-100 for travel time and basic inspection. Parts markup averages 25-40% above wholesale costs, and labor rates range $50-125 per hour depending on complexity and regional market conditions.

Recent Comments