Dealing with mysterious moisture problems, unusual energy bills, or persistent odors in your Maple Ridge home? These could be warning signs of appliance humidity issues that are silently causing thousands of dollars in damage while creating serious health and safety risks for your family.

Picture this: you’re running your dishwasher like always, but lately it’s been leaving dishes cloudy and the kitchen feels extra humid afterward. Or maybe your washing machine has developed that musty smell that won’t go away no matter how much bleach you use. What you might not realize is that these aren’t just annoying quirks – they’re early warning signs of humidity problems that could lead to major appliance failures, expensive water damage, and even electrical hazards that put your family at risk.

[IMAGE PLACEHOLDER FOR maple-ridge-home-appliance-humidity-warning-signs]

Living in Maple Ridge comes with incredible perks, but our coastal location creates the perfect storm for appliance-destroying humidity issues that most homeowners never see coming. With relative humidity regularly hitting 87.82% during peak months and staying consistently high year-round, our beautiful Pacific Northwest climate is actually working against every appliance in your home. The combination of persistent moisture, salt-laden sea air, and those dramatic temperature swings we experience creates conditions that can turn a simple maintenance issue into a cascading disaster affecting multiple systems throughout your house.

The really frustrating part? Most of these expensive problems are totally preventable when you understand what’s actually happening and take the right steps to protect your investment. After digging deep into the science behind humidity damage and talking with local repair experts who see these issues daily, I’ve discovered that the key isn’t just managing moisture – it’s understanding how our specific environmental conditions interact with modern appliances in ways that can either extend their life by years or destroy them prematurely.

Key Outtakes:

- High indoor humidity levels above 50% create corrosion and rust on metal components within appliances, compromising electrical conductivity and leading to short circuits and complete system failures

- Mold and mildew proliferate rapidly in humid conditions, colonizing wiring, circuit boards, and mechanical components within 24-48 hours of moisture exposure, creating both equipment damage and health risks

- Modern appliances contain 58% more complex electronic systems than previous generations, dramatically increasing potential failure points and vulnerability to humidity-induced damage

- Proper moisture control maintaining humidity between 30-50% prevents the majority of humidity-related appliance failures while also reducing overall home energy costs

- The cascade effect from single appliance failures can multiply repair costs by 2-3 times through secondary water damage and electrical problems affecting multiple systems

How Maple Ridge’s Coastal Climate Creates Perfect Conditions for Appliance Destruction

Let’s start with something that might surprise you – our gorgeous coastal location is actually working against your appliances every single day. While we’re enjoying those ocean breezes and mild temperatures, the reality is that Maple Ridge experiences relative humidity levels that regularly reach 87.82% during November, with summer months still maintaining around 69% humidity. Compare that to the EPA’s recommended indoor humidity range of 30-50%, and you’ll see we’re dealing with nearly double the moisture that most appliance manufacturers design their products to handle.

This isn’t just about feeling sticky on humid days. When your dishwasher, washing machine, or refrigerator operates in an environment with 80%+ humidity, every breath of air those appliances draw in carries massive amounts of water vapor that condenses on internal components. Think about what happens when you open a cold drink on a humid day – that condensation forming on the outside of the can is exactly what’s happening inside your appliances, except it’s happening continuously on electrical connections, circuit boards, and metal components that weren’t designed to stay wet.

The salt-laden air from our coastal location adds another layer of complexity that most generic appliance advice completely ignores. Salt particles carried by ocean winds can travel surprisingly far inland, gradually accumulating on and within household appliances where they accelerate corrosion processes. It’s not just about visible rust – we’re talking about microscopic salt deposits that create electrochemical reactions, turning every metal surface into a potential corrosion site when combined with the persistent moisture in our air.

What makes this particularly challenging for Maple Ridge homeowners is the interaction between our mineral-rich municipal water and the high humidity environment. When water evaporates from dishes in your dishwasher or clothes in your washing machine, it leaves behind mineral deposits that, in a high-humidity environment, never fully dry. Instead, these minerals create reactive surfaces that maintain moisture and accelerate the breakdown of nearby components. This combination of factors – coastal humidity, salt air, and mineral-rich water – creates a perfect storm that can reduce appliance lifespans by years compared to what you’d experience in drier climates.

The temperature fluctuations we experience throughout the year compound these problems through repeated expansion and contraction cycles. When humid air gets heated and cooled repeatedly – like what happens every time your refrigerator cycles or your dishwasher runs a heated dry cycle – it creates stress on seals, gaskets, and electrical connections. Over time, these thermal cycling events cause micro-cracks and seal failures that allow moisture to penetrate deeper into appliance components, accelerating the damage process exponentially.

The Mold Menace: How Humidity Turns Your Appliances Into Health Hazards

Here’s something that’ll wake you up – mold can begin growing in your appliances within 24-48 hours of moisture exposure, and once it gets established, it becomes nearly impossible to eliminate completely. We’re not talking about the obvious mold you can see and wipe away. I’m talking about mold colonies that establish deep within rubber gaskets, behind control panels, and in air circulation systems where they continuously release spores into your home’s air supply while gradually destroying the components they’re growing on.

Front-loading washing machines represent ground zero for this problem. Consumer Reports found that 16% of front-load washer owners report persistent mold and odor issues, and in Maple Ridge’s humid climate, that percentage is likely much higher. The rubber door gaskets that create watertight seals also create perfect moisture traps where mold can establish colonies that penetrate deep into the rubber material itself. You can clean and bleach these gaskets repeatedly, but the mold keeps coming back because the humid environment provides ideal growing conditions and the rubber material itself becomes compromised.

The health implications extend far beyond just appliance damage. When mold colonizes your HVAC system’s heat pump coils or air conditioning evaporator, it doesn’t just reduce efficiency – it turns your climate control system into a mold spore distribution network. Every time the system runs, it circulates mold spores throughout your entire home. The CDC identifies mold exposure as a significant risk factor for respiratory issues, making mold-contaminated appliances not just inconvenient but potentially dangerous for family members with asthma, allergies, or compromised immune systems.

What’s particularly insidious about appliance mold is that it often grows in places you can’t see or easily reach. Mold growing on refrigerator coils reduces heat exchange efficiency, forcing the compressor to work harder and draw more electrical current, which generates additional heat and creates even better conditions for mold growth. It’s a self-accelerating cycle where the presence of mold creates conditions that promote more mold while simultaneously damaging the appliance’s ability to function properly.

The modern washing machine manufacturers have actually started recognizing this as such a widespread problem that they’ve developed specific features to combat it. Whirlpool’s FreshFlow Vent system and GE’s UltraFresh technology automatically run drying cycles after wash cycles complete, reducing interior humidity from over 90% down to approximately 50%. This measurable humidity reduction can significantly slow mold colonization, but it only works if you maintain reasonable ambient humidity in the surrounding area.

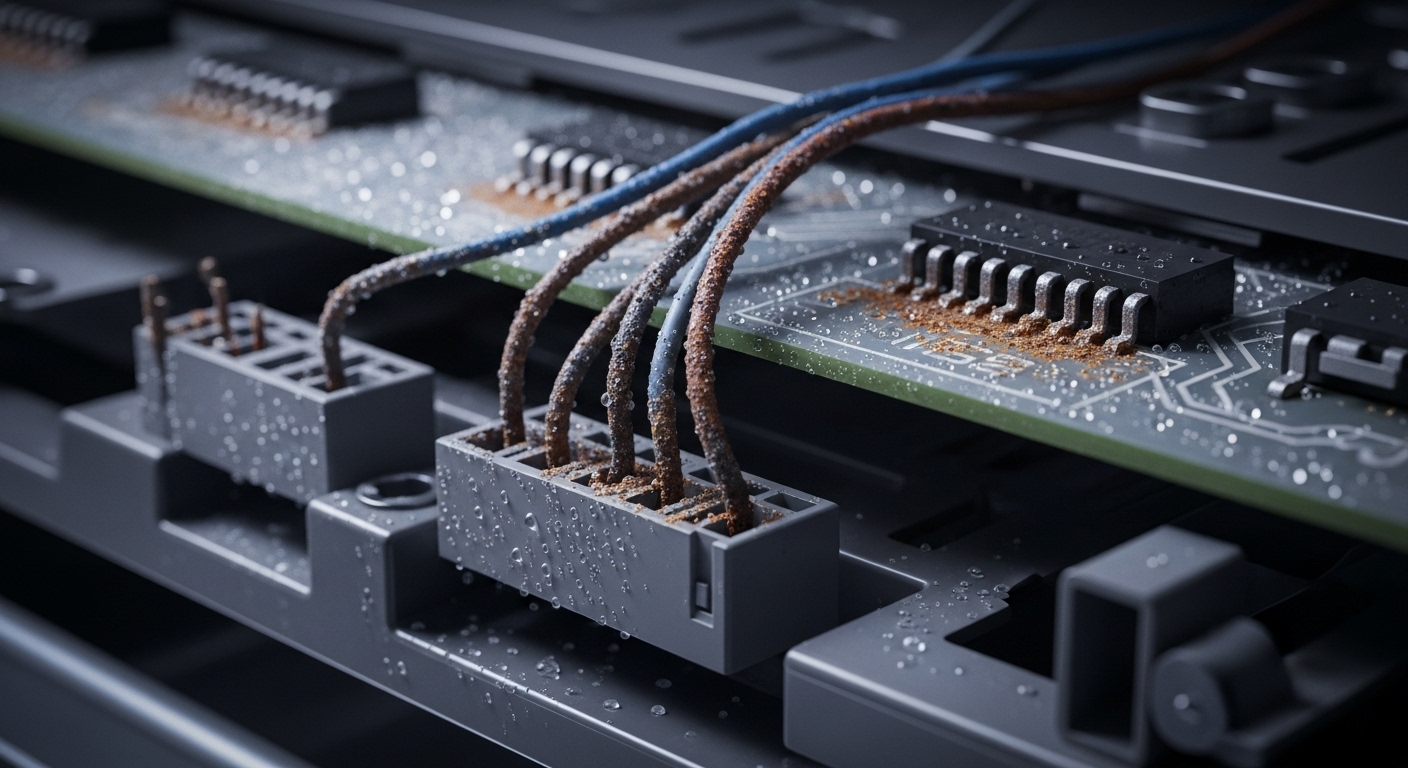

Electrical Failures and Corrosion: The Silent Killers of Modern Appliances

Now let’s talk about the most dangerous and expensive consequence of humidity problems – electrical failures that can create fire hazards, electrocution risks, and complete appliance destruction. Research examining humidity’s impact on electrical systems found that over 50% of electrical failures can be traced back to corrosion-related issues, and those statistics likely underestimate the problem in high-humidity coastal environments like ours.

Here’s what happens at the microscopic level: when moisture contacts metal electrical connections, it

Recent Comments