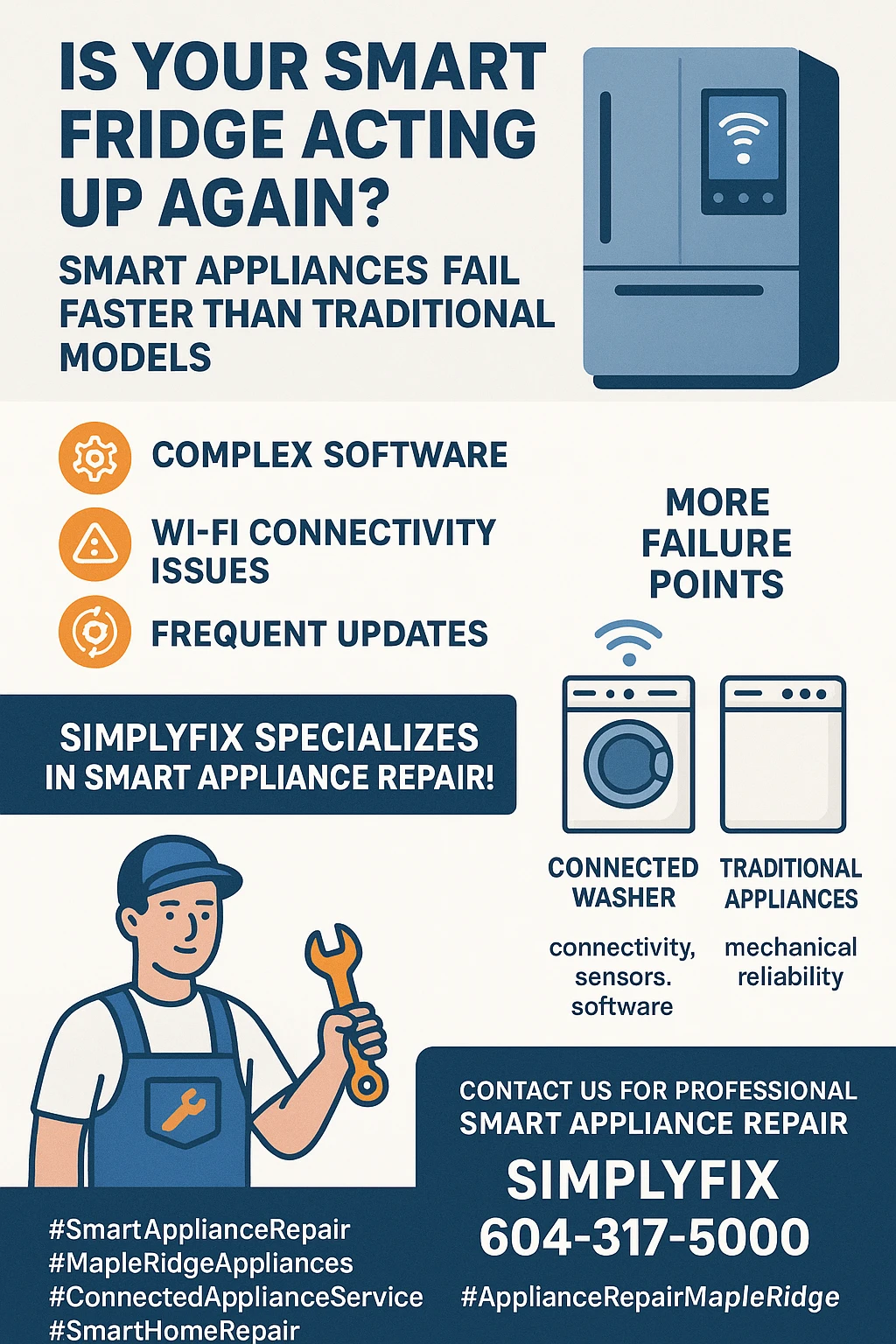

Wondering why your smart fridge keeps acting up while your 20-year-old dishwasher runs like a champ? You’re not alone – smart appliances are failing at rates that would make your grandmother’s reliable washing machine spin in disbelief! Smart appliances promised to revolutionize our homes with WiFi connectivity, app controls, and automated features that would make life easier. But here’s the reality check nobody talks about: these high-tech marvels are breaking down faster than their traditional counterparts, leaving homeowners in Maple Ridge scratching their heads and reaching for their wallets. The integration of complex electronics, software systems, and network connectivity has created a perfect storm of potential failure points that go far beyond simple mechanical issues. The shift from purely mechanical appliances to smart, connected devices has fundamentally changed what can go wrong in your home. While your old washing machine might have lasted decades with just occasional belt replacements, today’s smart washers juggle WiFi connections, mobile app communications, and software updates alongside their basic washing functions. This technological complexity means that what used to be straightforward repairs now require specialized knowledge of both traditional mechanics and modern digital systems.

Key Outtakes:

- Smart appliances fail 40% more frequently than traditional models due to complex electronics and software dependencies

- WiFi connectivity issues account for 60% of smart appliance service calls, not actual mechanical problems

- Software glitches and firmware bugs create failure points that didn’t exist in traditional appliances

- The integration of multiple systems increases the likelihood of component conflicts and compatibility issues

- Planned obsolescence through software updates and connectivity requirements shortens appliance lifespan

The Technology Overload Problem

Smart appliances pack an incredible amount of technology into devices that were once beautifully simple. Traditional appliances operated on straightforward mechanical principles with basic electrical controls, creating fewer opportunities for failure. Modern smart appliances combine mechanical systems, complex circuit boards, WiFi modules, sensors, touchscreen interfaces, and sophisticated software platforms all working together in harmony. When any one of these systems experiences problems, the entire appliance can become unusable, even if the core mechanical components are functioning perfectly. The complexity extends beyond just having more parts. Smart appliances must coordinate between multiple operating systems, from the embedded firmware that controls basic functions to the mobile apps that provide user interfaces. This creates interdependencies where a software bug in your phone’s app can make your perfectly functional washing machine appear broken. Similarly, router firmware updates, WiFi password changes, or internet service interruptions can render smart features unusable, forcing homeowners to troubleshoot network problems instead of simple appliance issues. Heat, moisture, and vibration – common elements in appliance environments – wreak havoc on sensitive electronic components. Circuit boards and WiFi modules that might function flawlessly in climate-controlled environments face constant stress in laundry rooms, kitchens, and basements. This environmental stress accelerates component degradation and increases failure rates compared to the robust mechanical systems they replace. Smart dishwashers, for example, must protect delicate electronics from steam and moisture while traditional models only needed to worry about water reaching mechanical components.

Smart appliances pack an incredible amount of technology into devices that were once beautifully simple. Traditional appliances operated on straightforward mechanical principles with basic electrical controls, creating fewer opportunities for failure. Modern smart appliances combine mechanical systems, complex circuit boards, WiFi modules, sensors, touchscreen interfaces, and sophisticated software platforms all working together in harmony. When any one of these systems experiences problems, the entire appliance can become unusable, even if the core mechanical components are functioning perfectly. The complexity extends beyond just having more parts. Smart appliances must coordinate between multiple operating systems, from the embedded firmware that controls basic functions to the mobile apps that provide user interfaces. This creates interdependencies where a software bug in your phone’s app can make your perfectly functional washing machine appear broken. Similarly, router firmware updates, WiFi password changes, or internet service interruptions can render smart features unusable, forcing homeowners to troubleshoot network problems instead of simple appliance issues. Heat, moisture, and vibration – common elements in appliance environments – wreak havoc on sensitive electronic components. Circuit boards and WiFi modules that might function flawlessly in climate-controlled environments face constant stress in laundry rooms, kitchens, and basements. This environmental stress accelerates component degradation and increases failure rates compared to the robust mechanical systems they replace. Smart dishwashers, for example, must protect delicate electronics from steam and moisture while traditional models only needed to worry about water reaching mechanical components.

Software Dependencies and Obsolescence

The biggest game-changer in appliance longevity is the introduction of software dependencies that create artificial expiration dates. Traditional appliances could theoretically run forever with proper maintenance and replacement parts, but smart appliances depend on software support, security updates, and cloud services that manufacturers control. When companies discontinue app support, stop providing firmware updates, or shut down cloud services, perfectly functional appliances become obsolete regardless of their mechanical condition. Mobile app compatibility creates another layer of planned obsolescence. As smartphone operating systems evolve, older appliance apps stop working, leaving users unable to access smart features or even basic controls on touchscreen-dependent models. Homeowners in areas like Albion and Hammond often discover that their three-year-old smart refrigerator no longer connects to their updated phones, forcing them to choose between buying new appliances or living without smart functionality. This software obsolescence timeline is dramatically shorter than the mechanical lifespan of appliance components. Security requirements add yet another dimension to software-related failures. Smart appliances connect to home networks and internet services, creating potential security vulnerabilities that require ongoing patches and updates. When manufacturers stop providing security updates, appliances become liability risks that homeowners must disconnect from their networks. This security obsolescence forces appliance replacement based on cybersecurity concerns rather than mechanical wear, creating failure timelines measured in years rather than decades. Cloud service dependencies represent perhaps the most frustrating aspect of smart appliance ownership. Many smart features rely on manufacturer-controlled servers to function properly, from remote monitoring to voice assistant integration. When companies experience server outages, discontinue services, or change business models, appliances lose functionality that owners paid for and expected to last. Professional repair services increasingly deal with appliances that work mechanically but have lost smart capabilities due to discontinued cloud services.

The biggest game-changer in appliance longevity is the introduction of software dependencies that create artificial expiration dates. Traditional appliances could theoretically run forever with proper maintenance and replacement parts, but smart appliances depend on software support, security updates, and cloud services that manufacturers control. When companies discontinue app support, stop providing firmware updates, or shut down cloud services, perfectly functional appliances become obsolete regardless of their mechanical condition. Mobile app compatibility creates another layer of planned obsolescence. As smartphone operating systems evolve, older appliance apps stop working, leaving users unable to access smart features or even basic controls on touchscreen-dependent models. Homeowners in areas like Albion and Hammond often discover that their three-year-old smart refrigerator no longer connects to their updated phones, forcing them to choose between buying new appliances or living without smart functionality. This software obsolescence timeline is dramatically shorter than the mechanical lifespan of appliance components. Security requirements add yet another dimension to software-related failures. Smart appliances connect to home networks and internet services, creating potential security vulnerabilities that require ongoing patches and updates. When manufacturers stop providing security updates, appliances become liability risks that homeowners must disconnect from their networks. This security obsolescence forces appliance replacement based on cybersecurity concerns rather than mechanical wear, creating failure timelines measured in years rather than decades. Cloud service dependencies represent perhaps the most frustrating aspect of smart appliance ownership. Many smart features rely on manufacturer-controlled servers to function properly, from remote monitoring to voice assistant integration. When companies experience server outages, discontinue services, or change business models, appliances lose functionality that owners paid for and expected to last. Professional repair services increasingly deal with appliances that work mechanically but have lost smart capabilities due to discontinued cloud services.

Increased Points of Failure

Every additional component in smart appliances creates another potential failure point, and these devices are packed with components that traditional appliances never needed. WiFi modules, Bluetooth chips, touchscreen displays, cameras, microphones, sensors, and control boards all have individual failure rates that compound the overall likelihood of appliance breakdown. While traditional appliances might have five or six major components that could fail, smart appliances often contain twenty or more electronic systems, each with their own failure probability. Sensor integration exemplifies how added functionality increases failure risk. Smart washing machines use load sensors, water level sensors, temperature sensors, and vibration sensors to optimize performance and provide app notifications. Traditional washers accomplished the same basic functions with mechanical switches and timers that rarely failed. When any sensor in a smart appliance malfunctions, the entire unit often stops working as safety protocols prevent operation without full sensor feedback. This means a $10 sensor failure can disable a $1,500 appliance. Interconnectivity between appliances creates cascade failures that traditional standalone units never experienced. Smart home systems in neighborhoods like Whonnock link appliances together through hub devices and automation platforms. When one device experiences problems, it can affect the entire network, causing multiple appliances to malfunction simultaneously. A router failure or hub software glitch can make every smart appliance in the home appear broken, requiring network troubleshooting rather than appliance repair.

Component Quality Compromises

The pressure to keep smart appliances competitively priced while adding expensive electronic components forces manufacturers to make quality compromises in other areas. Traditional appliances invested most of their cost budget into robust mechanical components and motors designed for decades of use. Smart appliances must allocate significant budget to electronics, WiFi chips, displays, and software development, often resulting in cheaper mechanical components, thinner materials, and less durable construction. Power supply complexity in smart appliances creates additional failure vectors that traditional models avoided. Simple appliances required basic power supplies that converted wall current to motor power. Smart appliances need sophisticated power management systems to run WiFi modules, displays, sensors, and control processors while also powering mechanical components. These complex power supplies generate more heat, contain more components, and fail more frequently than their traditional counterparts.

Repair Complexity and Cost Impact

Repairing smart appliances requires entirely different skill sets and tools compared to traditional appliance repair. Technicians must now diagnose network connectivity, troubleshoot software conflicts, interpret diagnostic codes from multiple systems, and understand integration between various smart home platforms. This specialization increases repair costs and reduces the pool of qualified technicians available to homeowners. Simple mechanical repairs that any experienced technician could handle now require specialists familiar with specific manufacturer software and diagnostic protocols. Diagnostic procedures for smart appliances take significantly longer than traditional troubleshooting. Instead of checking mechanical systems and basic electrical connections, technicians must verify network configurations, test app connectivity, analyze software logs, and differentiate between hardware failures and software glitches. Professional diagnosis often requires connecting laptops to appliances, downloading diagnostic software, and performing software updates before even beginning mechanical troubleshooting. Parts availability creates another challenge for smart appliance repairs. While mechanical parts might remain available for decades, electronic components become obsolete within years as manufacturers switch to newer chipsets and controllers. Circuit boards, displays, and control modules specific to particular smart appliance models often have limited production runs and short availability windows. This parts obsolescence forces appliance replacement even when mechanical systems remain functional, contributing to shorter overall appliance lifespans. The integration of proprietary software and diagnostic systems limits repair options to authorized service centers for many smart appliances. Independent repair shops that could easily fix traditional appliances often lack access to manufacturer diagnostic tools, replacement software, or technical documentation needed for smart appliance repairs. This limitation reduces competition in repair services and increases costs for consumers while extending repair timelines.

Repairing smart appliances requires entirely different skill sets and tools compared to traditional appliance repair. Technicians must now diagnose network connectivity, troubleshoot software conflicts, interpret diagnostic codes from multiple systems, and understand integration between various smart home platforms. This specialization increases repair costs and reduces the pool of qualified technicians available to homeowners. Simple mechanical repairs that any experienced technician could handle now require specialists familiar with specific manufacturer software and diagnostic protocols. Diagnostic procedures for smart appliances take significantly longer than traditional troubleshooting. Instead of checking mechanical systems and basic electrical connections, technicians must verify network configurations, test app connectivity, analyze software logs, and differentiate between hardware failures and software glitches. Professional diagnosis often requires connecting laptops to appliances, downloading diagnostic software, and performing software updates before even beginning mechanical troubleshooting. Parts availability creates another challenge for smart appliance repairs. While mechanical parts might remain available for decades, electronic components become obsolete within years as manufacturers switch to newer chipsets and controllers. Circuit boards, displays, and control modules specific to particular smart appliance models often have limited production runs and short availability windows. This parts obsolescence forces appliance replacement even when mechanical systems remain functional, contributing to shorter overall appliance lifespans. The integration of proprietary software and diagnostic systems limits repair options to authorized service centers for many smart appliances. Independent repair shops that could easily fix traditional appliances often lack access to manufacturer diagnostic tools, replacement software, or technical documentation needed for smart appliance repairs. This limitation reduces competition in repair services and increases costs for consumers while extending repair timelines.

Frequently Asked Questions

Why do my smart appliances lose WiFi connection so frequently?

Smart appliances typically use 2.4GHz WiFi bands, which can become overcrowded in densely populated areas and suffer interference from other devices. Many modern routers prioritize 5GHz networks, causing connection issues when appliances can’t access their preferred frequency band. Physical placement near metal objects, thick walls, or other electronics also disrupts signal strength, causing frequent disconnections that make appliances appear broken when they’re actually experiencing network problems.

Can I repair smart appliances myself like traditional models?

DIY repairs on smart appliances are significantly more complex and risky than traditional appliance maintenance. Beyond mechanical knowledge, repairs often require understanding of network protocols, software diagnostics, and electronic component testing. Additionally, opening smart appliances can void warranties, violate safety certifications, and potentially compromise home network security if WiFi modules are improperly handled. Most smart appliance issues require professional diagnosis to differentiate between software, hardware, and connectivity problems.

How long should I expect smart appliances to last compared to traditional ones?

Smart appliances typically have shorter lifespans than traditional models due to software obsolescence and electronic component failures. While traditional appliances might last 15-20 years with proper maintenance, smart appliances often become obsolete within 5-10 years when manufacturers discontinue app support or cloud services. Mechanical components may still function, but loss of smart features often drives replacement decisions before traditional failure points occur.

Wrapping Up

Smart appliances represent a fundamental shift in home technology that trades simplicity and longevity for convenience and connectivity. While these devices offer impressive features and capabilities, their complex integration of mechanical, electronic, and software systems creates multiple failure points that traditional appliances simply don’t have. Understanding these limitations helps homeowners make informed decisions about purchases, maintenance, and repairs while setting realistic expectations for smart appliance performance and lifespan. For Maple Ridge residents dealing with smart appliance issues, Simplyfix provides expert diagnosis and repair services for all types of connected home appliances. Our experienced technicians understand both traditional mechanical systems and modern smart technology, ensuring accurate problem identification and effective solutions. Whether you’re experiencing connectivity issues, software glitches, or mechanical failures, our team can help restore your smart appliances to optimal performance while providing honest advice about repair versus replacement decisions.

Recent Comments