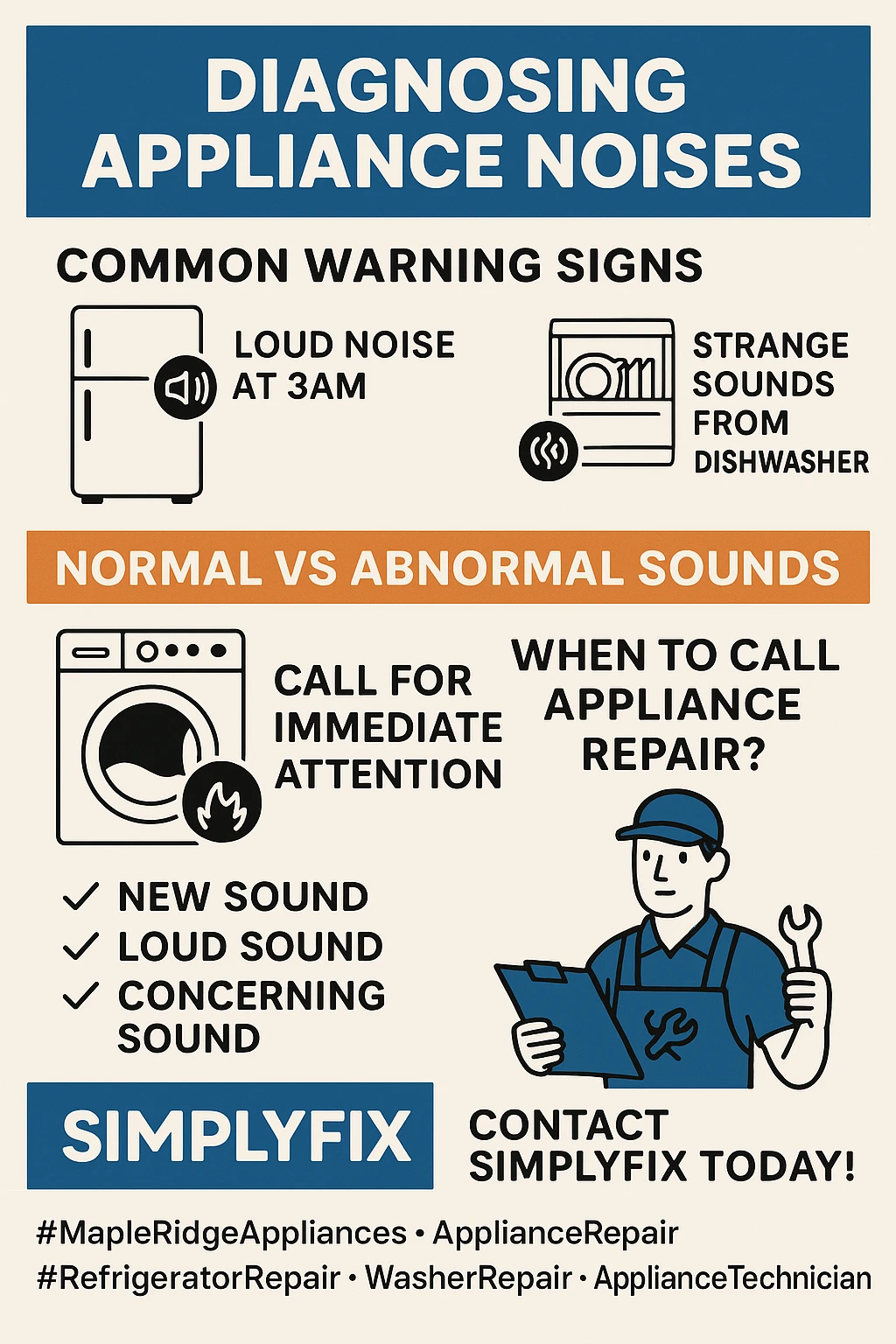

Hearing strange sounds from your appliances but unsure whether they signal a brewing disaster or just normal operation? Understanding the difference between harmless operational noises and warning signs can save Maple Ridge homeowners hundreds in unnecessary repairs and prevent costly appliance failures.Picture this: you’re enjoying a quiet evening in your Maple Ridge home when suddenly your refrigerator starts making a sound you’ve never heard before. Your heart sinks as you wonder if your appliance is about to give up the ghost, leaving you with spoiled groceries and a hefty repair bill. The truth is, appliances naturally make various sounds during normal operation, but distinguishing between routine noise and genuine warning signs requires some know-how. From the gentle hum of a working compressor to the rhythmic swishing of dishwasher spray arms, many sounds indicate your appliances are functioning exactly as designed.However, certain noises demand immediate attention and can prevent minor issues from escalating into major breakdowns. Understanding these audio cues becomes particularly important for Maple Ridge residents, where temperature fluctuations and seasonal changes can affect appliance performance and create additional sound variations. This comprehensive guide will help you decode what your appliances are telling you through their sounds, when to attempt simple troubleshooting, and when professional intervention becomes necessary.

Key Outtakes:

- Normal appliance sounds include gentle humming, water filling, and brief operational clicks, while grinding, banging, and squealing indicate potential problems requiring attention

- Most refrigerator humming and dishwasher water sounds are normal, but persistent loud buzzing or metal-on-metal grinding sounds signal immediate repair needs

- Simple troubleshooting like checking appliance level and clearing obstructions can resolve many noise issues before calling professionals

- Professional repair costs in the Maple Ridge area typically range from $100-$400, making early diagnosis crucial for preventing costlier replacements

- Regular maintenance and proper loading techniques can prevent most noise-related appliance problems from developing

Understanding the Language of Appliance Sounds

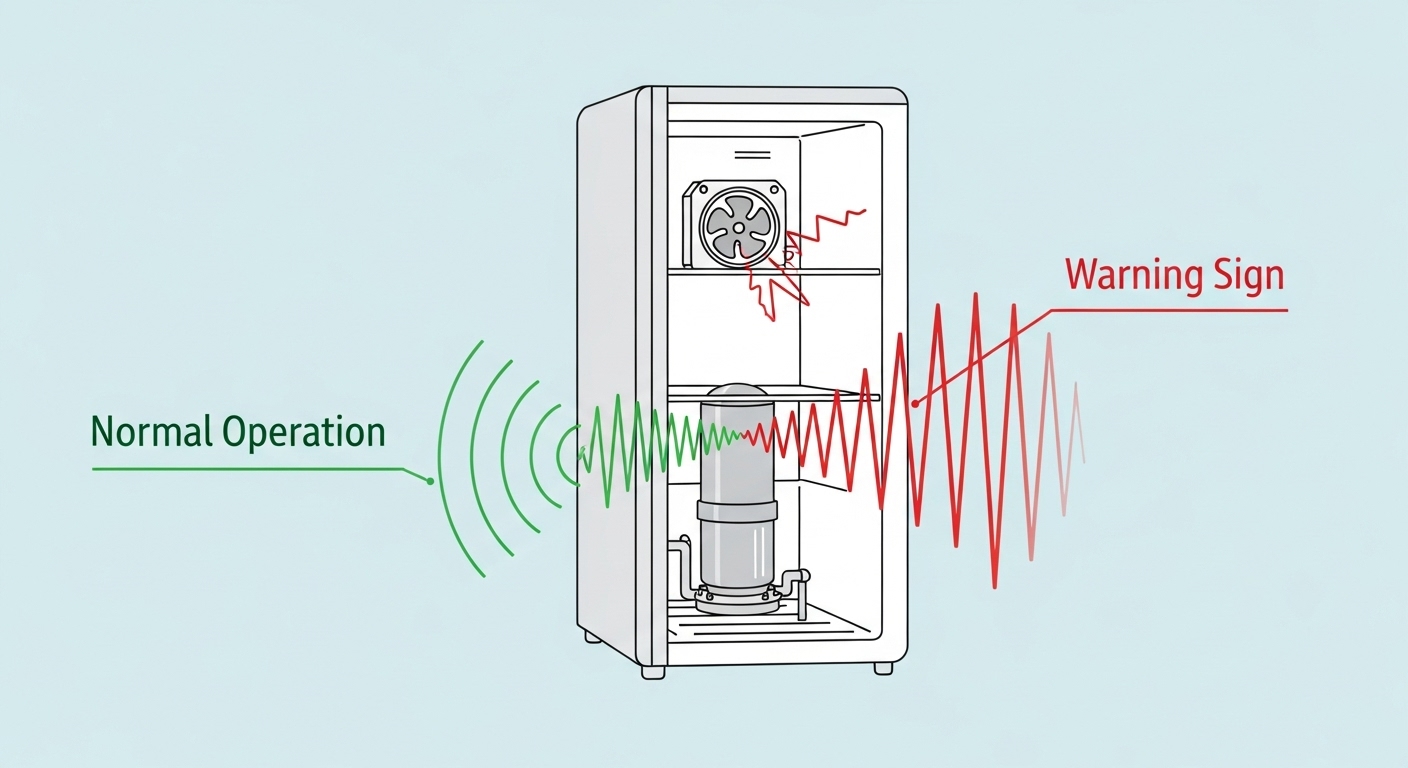

Every appliance in your home communicates through sound, creating a unique acoustic signature that reveals its operational status. Learning to interpret these sounds serves as your first line of defense against costly repairs and unexpected breakdowns. Normal operational sounds typically fall into predictable patterns that correspond to specific functions, such as compressor cycling, water flow, or motor operation. These baseline sounds help establish what’s typical for each appliance and provide reference points for identifying when something changes.The key lies in recognizing consistency versus irregularity in sound patterns. A refrigerator that hums quietly and consistently during cooling cycles operates normally, while one that suddenly develops a loud, grinding noise signals mechanical distress. Similarly, the rhythmic swooshing of dishwasher spray arms indicates proper water circulation, but sharp banging or grinding sounds suggest foreign objects or component failure. Understanding these distinctions empowers homeowners to respond appropriately rather than panicking at every operational sound.Seasonal variations add another layer of complexity, particularly in Maple Ridge’s variable climate. Temperature fluctuations cause thermal expansion in appliance components, leading to more creaking and popping sounds during seasonal transitions. Metal components expand and contract differently than plastic parts, creating temporary noise variations that aren’t necessarily problematic. Recognizing these climate-related sound changes prevents unnecessary service calls while maintaining awareness of genuine mechanical issues.Environmental factors within your home also influence appliance noise transmission. Older Maple Ridge homes with hardwood floors and minimal insulation may amplify appliance sounds, making normal operations seem louder than in newer, well-insulated properties. Conversely, appliances installed on concrete floors or in insulated utility rooms may produce muffled sounds that mask early warning signs of mechanical problems.

Refrigerator Noise Diagnosis

Your refrigerator represents the hardest-working appliance in your home, operating continuously to maintain food safety and freshness. Understanding its normal sound patterns becomes crucial for early problem detection and preventing costly repairs. A consistent, low hum during refrigeration cycles indicates proper compressor operation, while clicking sounds every few hours typically signal normal defrost timer cycling. These sounds demonstrate your refrigerator’s various systems coordinating to maintain optimal temperature control.However, certain refrigerator sounds immediately warrant attention and potential professional intervention. If your refrigerator produces an extremely loud buzzing sound rather than a soft hum, the compressor may be struggling or failing, requiring immediate diagnosis. Compressor replacement ranks among the most expensive refrigerator repairs, often costing more than replacing older units entirely. Early detection of compressor distress through sound changes can sometimes allow for less invasive repairs or help inform replacement timing decisions.Grinding or scraping noises often indicate problems with internal fan motors, which circulate air throughout refrigerator and freezer compartments. These sounds may intensify when doors open or during specific cooling cycles, helping pinpoint the affected component. Fan motor issues typically cost less to repair than compressor problems but require prompt attention to prevent secondary damage to other refrigeration components.Unusual clicking, popping, or crackling sounds that occur frequently rather than during normal defrost cycles may indicate problems with electrical components or refrigerant flow. These sounds often precede more serious mechanical failures, making early diagnosis particularly valuable. Temperature monitoring alongside sound changes provides additional diagnostic information, as struggling components often affect cooling performance before complete failure occurs.Water-related sounds present another diagnostic category, as refrigerators with ice makers or water dispensers produce additional operational noises. Normal water sounds include brief filling cycles, ice dropping into storage bins, and occasional drainage during defrost cycles. However, continuous water running, loud filling sounds, or unusual gurgling may indicate problems with water lines, valves, or drainage systems requiring professional attention.

Dishwasher Sound Analysis

Modern dishwashers orchestrate complex washing cycles that produce predictable sound patterns during normal operation, making unusual noises relatively easy to identify. Normal dishwasher sounds include water filling at cycle initiation, spray arms rotating and distributing water, detergent dispensing mechanisms activating, and drainage pumping at cycle completion. These sounds follow logical sequences that correspond to visible cycle indicators and typical program durations.Water-related sounds dominate normal dishwasher operation and provide valuable diagnostic information about system performance. The initial filling sound should be steady and conclude within a reasonable timeframe, typically two to three minutes depending on your home’s water pressure. High-pitched sounds during filling may indicate insufficient water pressure, common in older Maple Ridge neighborhoods with aging infrastructure, or problems with inlet valves requiring adjustment or replacement.Grinding noises represent the most serious dishwasher sound concern and almost never indicate normal operation. These sounds typically result from foreign objects lodging in chopper blade areas or pump mechanisms, potentially causing expensive damage if not addressed promptly. Common culprits include pieces of broken glass, small utensils, or food debris that bypassed the filter system. Immediate cycle interruption and careful inspection can prevent minor obstructions from escalating into pump replacements.Unusual banging or rattling during wash cycles often indicates problems with spray arm operation or dish loading patterns. Spray arms may become clogged with food particles or mineral deposits, causing erratic rotation and impact sounds. Alternatively, improperly loaded dishes may interfere with spray arm movement, creating collision noises and potentially damaging both dishes and spray mechanisms. Understanding these operational sounds helps distinguish between loading issues and mechanical problems requiring professional attention.Drainage sounds provide additional diagnostic information about dishwasher performance and potential blockages. Normal drainage should sound steady and complete within a few minutes of cycle conclusion. Gurgling, backing up sounds, or incomplete drainage may indicate clogs in disposal connections, drain hoses, or internal pump mechanisms. These issues often start gradually and worsen over time, making early detection and intervention particularly valuable for preventing water damage and expensive repairs.

Spray Arm and Wash Motor Diagnostics

Spray arm operation creates distinctive sound patterns that reveal important information about water circulation and cleaning effectiveness. Properly functioning spray arms produce consistent whooshing or swishing sounds as they rotate and distribute water throughout the dishwasher interior. Irregular or intermittent spray sounds may indicate partial blockages, worn bearings, or calcium buildup affecting rotation mechanisms.Wash motor problems typically manifest as unusual grinding, squealing, or laboring sounds during active wash cycles. These motors work harder when spray arms encounter resistance or when water circulation becomes restricted, creating stress indicators audible to attentive homeowners. Early detection of wash motor strain can prevent complete failure and the associated repair costs that often exceed several hundred dollars.

Washing Machine Noise Troubleshooting

Washing machines produce various operational sounds throughout their wash, rinse, and spin cycles, making normal versus abnormal noise identification particularly important for preventing costly repairs. Understanding these sound patterns helps homeowners distinguish between simple load balancing issues and serious mechanical problems requiring professional intervention. The most common washing machine noise complaint involves loud banging during spin cycles, which typically results from load imbal

Recent Comments