Why Your Appliances Keep Breaking Down After Repairs: Understanding the Root Causes Behind Recurring Issues in Maple Ridge Homes

Frustrated by your dishwasher acting up again just months after that expensive repair, or wondering why your dryer keeps making those strange noises even after the technician “fixed” it? You’re not alone – recurring appliance failures plague Maple Ridge homeowners more than you might think, and the root causes go way deeper than just bad luck.

Picture this: you shell out $300 to fix your washing machine, only to have it start leaking again three weeks later. Or maybe your refrigerator stops cooling properly just two months after a repair that was supposed to solve the exact same issue. If this sounds familiar, you’re experiencing what thousands of homeowners face every year – the maddening cycle of recurring appliance breakdowns that seem to happen no matter how much money you throw at the problem.

The truth is, most recurring appliance failures aren’t random occurrences or signs that you need to replace everything in your kitchen. Instead, they’re usually the result of specific, identifiable issues that range from poor diagnostic practices to environmental factors unique to our Pacific Northwest location. Understanding these root causes can save you hundreds of dollars in unnecessary repeat repairs and help you make smarter decisions about your home’s appliances.

What makes this particularly challenging for Maple Ridge residents is that our coastal climate, water quality, and local service landscape create unique conditions that many generic repair approaches simply don’t address. From the humidity that can wreak havoc on electronic components to the mineral-rich water that clogs internal systems, our local environment plays a bigger role in appliance longevity than most homeowners realize.

Key Outtakes:

- Most recurring appliance failures stem from incorrect initial diagnosis rather than the actual repair work performed, with technicians often replacing the wrong components

- Modern appliances contain significantly more complex electronic systems that increase failure rates by 58% compared to previous decades, creating more potential breakdown points

- Preventive maintenance programs can extend appliance lifespan by 3-5 years while reducing emergency repair costs by up to 80%

- Poor quality repair services often use inferior replacement parts or skip critical diagnostic steps, leading to repeat failures within months

- Environmental factors specific to Maple Ridge, including water quality and coastal humidity, accelerate appliance degradation when not properly addressed

The Hidden Problem: Misdiagnosis and Surface-Level Repairs

The biggest culprit behind recurring appliance breakdowns isn’t faulty parts or bad craftsmanship – it’s misdiagnosis. When your dryer stops heating properly, many technicians immediately assume the heating element has failed and replace it without investigating the sensors, timers, or control boards that actually communicate with that heating element. This approach might restore basic function temporarily, but it doesn’t address the underlying issue that caused the heating element to malfunction in the first place.

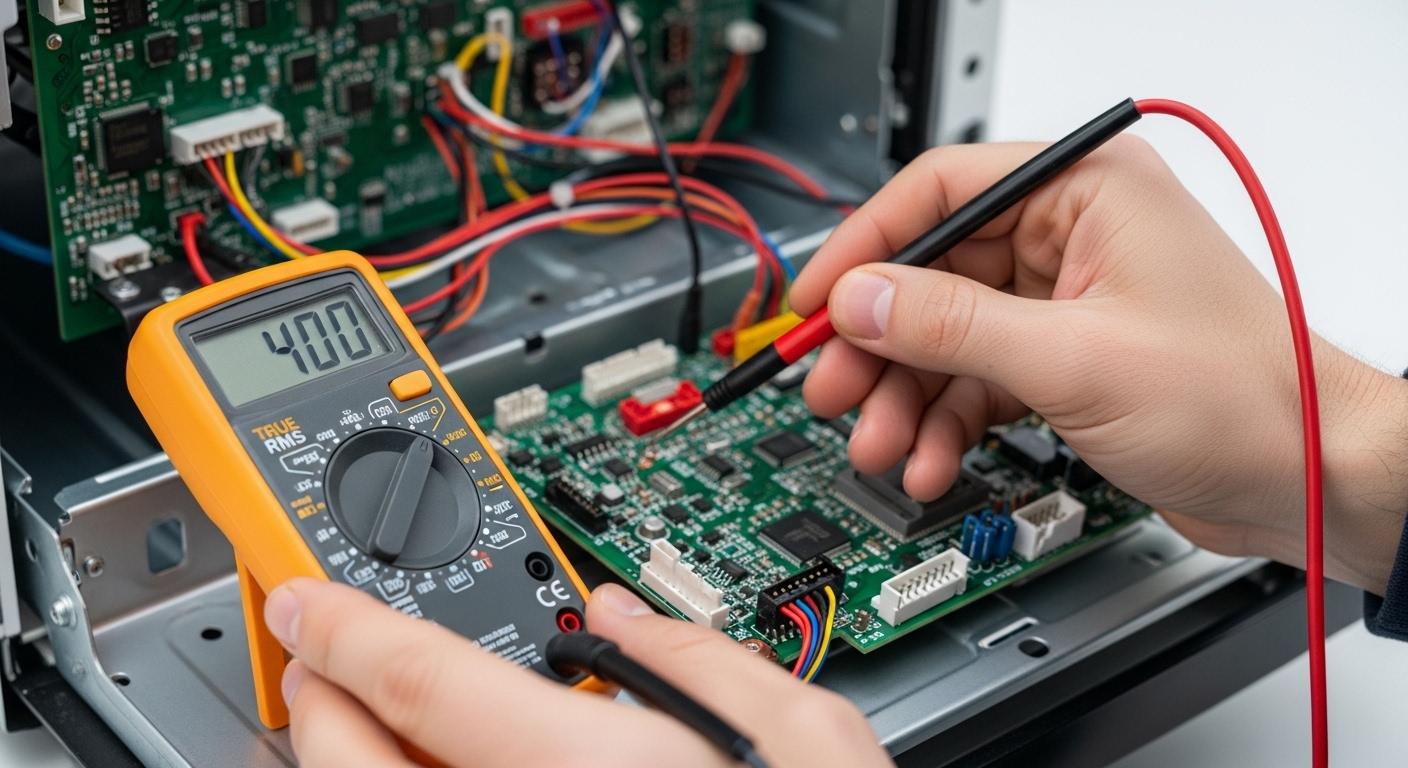

Modern appliances operate as integrated systems where individual components work together in complex ways. When one part fails, it’s often because another component has been sending incorrect signals, operating outside normal parameters, or creating conditions that stress the failing part beyond its design limits. A qualified technician should use specialized diagnostic equipment like True RMS multimeters, manifold gauges, and temperature probes to properly assess the entire system’s condition before making any repairs.

Unfortunately, many repair services prioritize speed over thoroughness, adopting what I call the “quick fix” mentality. They focus on getting your appliance running again as quickly as possible rather than conducting comprehensive evaluations that identify all contributing factors. This approach might seem cost-effective initially, but it almost always leads to repeat service calls when the root cause eventually manifests in a different way.

The reassembly process presents another critical failure point that many services underestimate. Complex modern appliances like washing machines require precise reassembly procedures to function properly. When technicians rush through this process or skip recommended calibration steps, they often introduce new problems that weren’t present before the repair. Simple oversights like forgetting to properly secure internal components or failing to reconnect sensors can create cascading failures throughout the system.

What makes this particularly frustrating is that these issues often don’t manifest immediately. Your appliance might work perfectly for the first few weeks after repair, only to develop new problems once the improperly installed components begin to shift, vibrate loose, or operate under stress. By the time symptoms appear, it’s often difficult to connect the new problems to the original repair work, leaving homeowners feeling like they’re fighting an endless battle against defective appliances.

The Impact of Inferior Parts and Shortcuts

Even when technicians correctly diagnose problems, the quality of replacement parts can determine whether your repair lasts months or years. Many repair services cut costs by using generic aftermarket parts instead of Original Equipment Manufacturer (OEM) components, and while these parts might function initially, they often lack the durability and precise specifications needed for long-term reliability.

This issue connects to a broader trend in appliance manufacturing where companies intentionally use cheaper, easily worn-out components as part of planned obsolescence strategies. Appliances frequently break down right after warranty expiration precisely because manufacturers design them with components that will fail predictably. When repair services compound this problem by using even cheaper replacement parts, they virtually guarantee future failures.

The authorization issue adds another layer of complexity. Many high-end appliances require manufacturer-certified technicians using authorized parts to maintain warranty coverage. When homeowners choose unauthorized repair services to save money, they often void their warranties and lose recourse when subsequent failures occur. This creates a particularly difficult situation where the cost savings from cheaper repairs get wiped out by the loss of warranty protection.

Power quality issues represent another often-overlooked factor that can destroy expensive control boards and electronic components. Power surges can instantly fry control boards, yet many repair services don’t assess or address the electrical conditions that might have contributed to the original failure. Without proper surge protection or electrical system evaluation, even perfect repairs using OEM parts can fail again when the next storm hits.

The diagnostic fee structure often reveals service quality differences. Reputable services typically charge diagnostic fees that they apply toward repair costs, reflecting the time and expertise required for proper evaluation. Services offering “free diagnostics” often compensate by cutting corners in the actual diagnostic process or inflating repair costs, ultimately providing less value despite the apparent savings.

Modern Appliance Complexity and Failure Patterns

Today’s appliances bear little resemblance to the simple, mechanical units that lasted decades with minimal maintenance. Modern appliances with computer controls, Wi-Fi connectivity, and multiple sensors have exponentially increased failure rates compared to their simpler predecessors. What used to be straightforward mechanical systems controlled by basic timers and switches have evolved into sophisticated networks of electronic components that communicate constantly and depend on precise calibration to function properly.

The statistics tell a concerning story about this increased complexity. More than 50% of homeowners experienced appliance issues in the last year, with repair requests increasing by 58% from 2022 to 2023. This dramatic rise correlates directly with the integration of smart features, touchscreen controls, and automated systems that introduce multiple new points of potential failure.

Smart home integration creates particularly challenging repair scenarios that traditional appliance technicians aren’t equipped to handle. When your smart refrigerator loses Wi-Fi connectivity or your connected dishwasher stops responding to app commands, the problem might be software-related, network-related, or involve complex interactions between multiple systems. Many repair services approach these issues with traditional diagnostic methods, leading to misdiagnosis and ineffective repairs.

The reduced repairability of modern designs compounds these problems. Manufacturers have moved toward lighter-weight construction using integrated components that can’t be easily separated or replaced individually. When one part of an integrated circuit board fails, the entire expensive assembly often requires replacement, dramatically increasing repair costs and reducing the economic viability of fixing rather than replacing appliances.

Electronics, shock absorbers, bearings, doors, and pumps represent the most common failure points in modern washing machines, while circulation pumps and electronic controls cause the majority of dishwasher problems. Understanding these patterns helps homeowners recognize when they’re dealing with inherent design limitations rather than isolated component failures, informing better decisions about repair versus replacement.

Environmental Factors Affecting Maple Ridge Appliances

Living in

Recent Comments