Wondering why your expensive appliances keep breaking down just years after installation, costing you thousands in premature replacements? The culprit might not be the appliances themselves, but where you placed them in your Maple Ridge home.

Picture this nightmare scenario that’s playing out in kitchens across Maple Ridge right now: you’ve invested fifteen thousand dollars in beautiful new appliances, only to watch your refrigerator’s compressor fail after just six years instead of the expected thirteen. Your dishwasher starts leaving gritty residue on dishes within eighteen months. Your dryer takes twice as long to dry clothes while your energy bills skyrocket. Most homeowners blame bad luck or poor manufacturing, but the real problem runs much deeper.

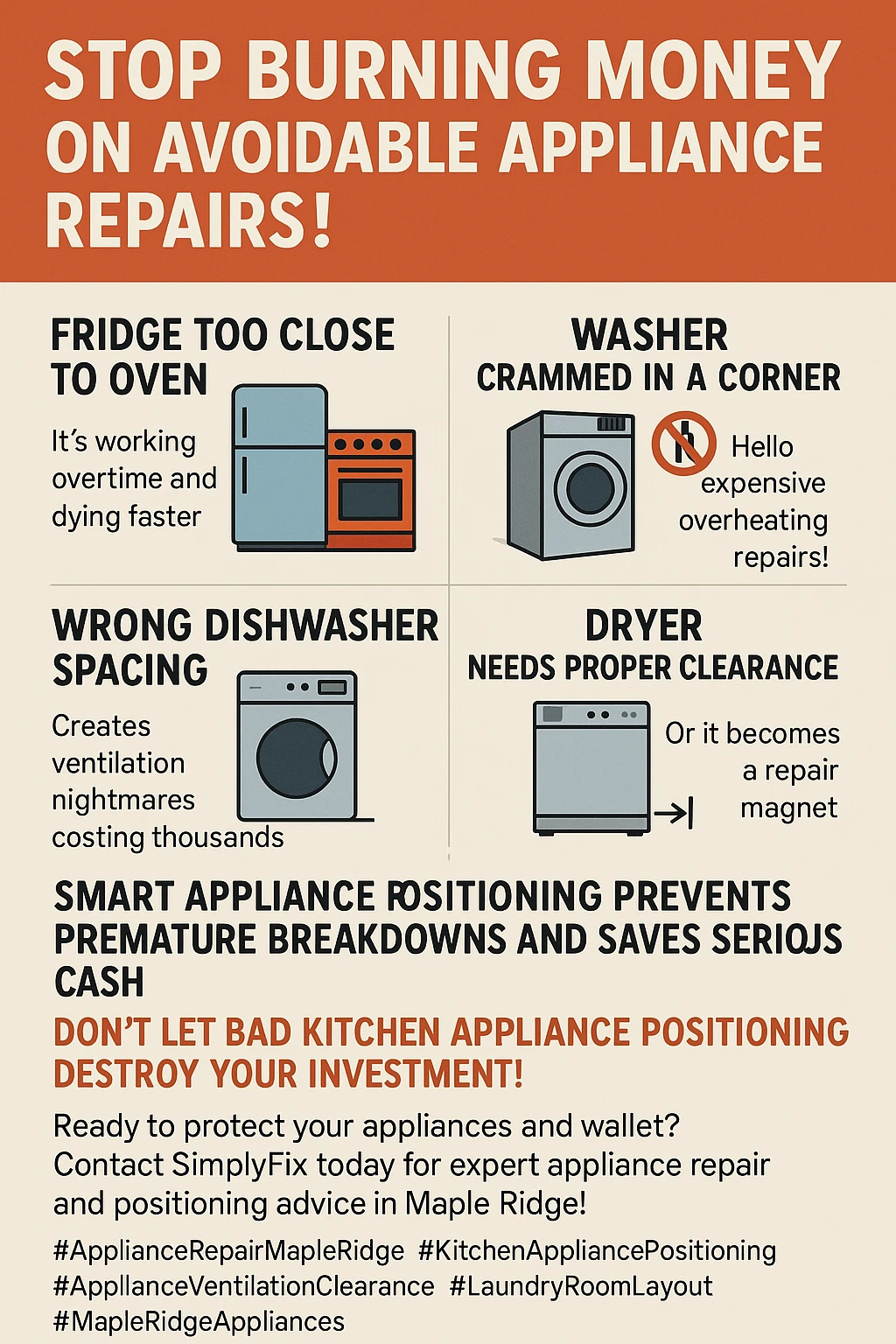

The truth is that improper appliance placement systematically destroys your investment through a combination of thermal stress, moisture damage, and restricted airflow that forces appliances to work exponentially harder than designed. When you position a refrigerator too close to your stove, place a dishwasher without adequate clearance, or install a dryer with insufficient ventilation, you’re essentially programming these expensive machines for premature failure. For Maple Ridge homeowners specifically, our coastal climate’s elevated humidity levels amplify these problems dramatically, creating conditions that can reduce appliance lifespans by three to five years while generating thousands of dollars in unnecessary repair costs.

What makes this particularly frustrating is that proper appliance placement costs absolutely nothing during the design phase, yet saves homeowners massive expenses over the lifetime of their kitchen and laundry investments. Understanding how placement mistakes destroy appliances—and knowing the simple adjustments that prevent these failures—represents one of the most valuable pieces of information any homeowner can possess.

Key Outtakes:

- Improper refrigerator placement forces compressors to work 30-50% harder, reducing lifespan from 13-15 years to just 7-10 years while costing up to $950 in premature compressor replacement

- Maple Ridge’s humid climate accelerates electronic component failure when appliances lack adequate clearance, with moisture damage beginning at humidity levels exceeding 50%

- Heat and steam from cooking appliances destroy kitchen cabinetry through steam burns and delamination, requiring $5,000-$15,000 in cabinet replacement costs

- Inadequate ventilation clearances create thermal stress that reduces all appliance lifespans by 20-40% while increasing energy consumption by 15-20% annually

- Emergency appliance repairs from placement-related failures cost four times more than preventive maintenance, with accumulated costs often exceeding replacement value

The Kitchen Work Triangle: Where Most Placement Mistakes Begin

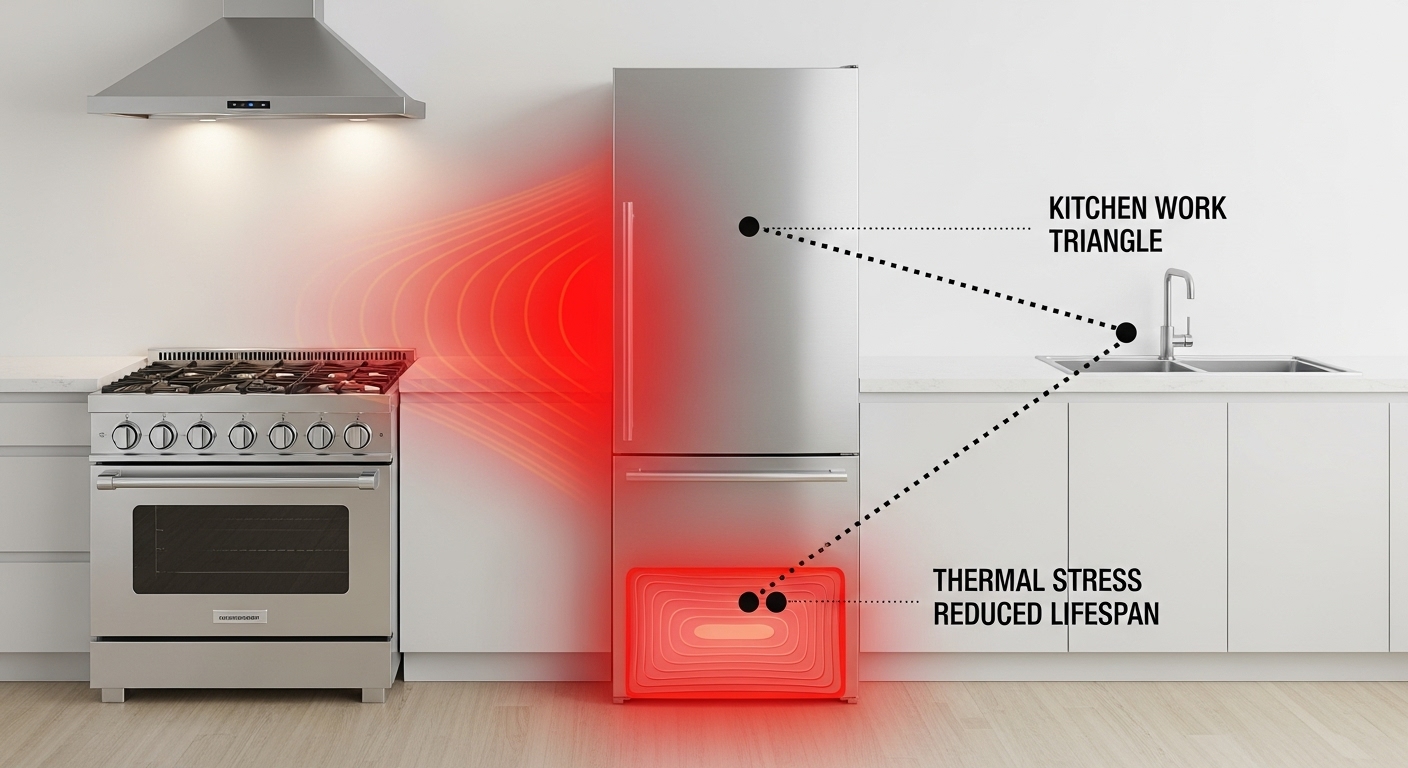

The foundation of proper appliance placement starts with understanding the kitchen work triangle, yet this principle is catastrophically misapplied in most Maple Ridge homes. The work triangle connects your three primary work centers—the refrigerator, sink, and cooking surface—and when configured incorrectly, it forces appliances to operate under conditions that accelerate component failure. Design guidelines specify that the sum of distances between these three points should total no more than twenty-six feet, with no single leg measuring less than four feet or more than nine feet. However, the critical factor most homeowners miss is how improper work triangle design creates thermal stress conditions that systematically destroy expensive appliances.

When your refrigerator sits too close to heat-generating appliances like stoves, ovens, or even dishwashers, the cooling system must work exponentially harder to maintain proper temperatures. The compressor—which typically costs five hundred to nine hundred fifty dollars to replace—cycles more frequently as it struggles against the ambient heat generated by nearby cooking appliances. This thermal stress doesn’t just increase energy bills by fifteen to twenty percent annually; it literally shortens the refrigerator’s lifespan from an expected thirteen to fifteen years down to just seven to ten years of service.

The positioning requirements for refrigerators extend beyond simple distance measurements to include critical ventilation clearances that most installation guides overlook. Your refrigerator needs at least two to three inches of space behind and on the sides to allow proper heat dissipation through the coils and vents designed to release warmth during cooling cycles. When appliances get pushed flush against walls or wedged tightly between cabinets, the warm air has nowhere to escape, creating a feedback loop where the refrigerator generates more heat while simultaneously losing its ability to dissipate that heat effectively.

For Maple Ridge homeowners specifically, the regional humidity compounds these placement problems exponentially. When ambient humidity exceeded fifty percent—which happens frequently in our coastal climate—moisture begins infiltrating appliance housings through microscopic gaps. This moisture creates electrical pathways that disrupt normal component operation while simultaneously accelerating corrosion of metal parts. The combination of inadequate clearance, thermal stress from nearby heat sources, and moisture infiltration creates ideal conditions for catastrophic compressor failure that often costs more to repair than the appliance is worth.

The work triangle principle also determines optimal positioning for your primary sink and cooking surface, creating ripple effects throughout your kitchen’s appliance ecosystem. When the sink sits too far from the dishwasher—more than thirty-six inches according to design guidelines—homeowners tend to pre-rinse dishes more extensively, causing both higher water usage and increased steam generation that affects nearby electronics. Similarly, cooking surfaces positioned incorrectly relative to ventilation systems fail to capture steam and grease effectively, allowing these damaging elements to settle on cabinet surfaces and infiltrate appliance housings throughout the kitchen.

Ventilation Failures That Cost Thousands in Cabinet and Appliance Damage

Proper ventilation represents the most underestimated factor in appliance longevity, yet ventilation failures account for some of the most expensive damage patterns plaguing Maple Ridge kitchens. When homeowners install range hoods at incorrect heights or fail to provide adequate steam venting for appliances, they create conditions that simultaneously destroy both the appliances themselves and surrounding cabinetry through concentrated heat and moisture exposure. The financial consequences of these ventilation mistakes often exceed the entire cost of the original appliance investment.

Range hood installation height directly determines ventilation effectiveness and represents one of the most common mistakes in contemporary kitchen design. Gas cooktops require range hood installation at twenty-four to thirty inches above the cooking surface, while electric cooktops need twenty to twenty-four inches, and induction cooktops require thirty to thirty-six inches clearance. Installing range hoods outside these specifications creates serious consequences: too high reduces ventilation capability dramatically, allowing cooking emissions to disperse throughout the kitchen rather than being captured and expelled, while too low risks hood damage from concentrated heat and steam rising from cooking surfaces.

The regional climate in Maple Ridge makes proper range hood specification even more critical because cooking steam and moisture persist in the air three to five times longer than in drier climates. When range hoods fail to capture cooking emissions effectively, this moisture doesn’t simply dissipate—it infiltrates electronic control systems in nearby appliances while simultaneously beginning the destructive process of cabinet damage through repeated wetting and drying cycles. Wood cabinets develop characteristic steam burns manifesting as white films on surfaces, while thermofoil and melamine cabinets experience discoloration or complete delamination when exposed to concentrated steam over time.

Over-the-range microwaves present particularly costly ventilation challenges that many Maple Ridge homeowners discover only after expensive damage occurs. These appliances come in two primary venting configurations: top venting units with small vents on the unit’s upper surface, and tilt-up venting models that push steam upward through opening vents. Standard fifteen-inch deep cabinets positioned above top-venting microwaves will be completely destroyed through constant exposure to rising steam and hot vapor. The cabinet destruction isn’t gradual—it often manifests as sudden delamination or melting that requires complete cabinet replacement costing five thousand to ten thousand dollars or more.

Dryer venting failures create an entirely separate category of expensive consequences, particularly dangerous in Maple Ridge’s moisture-rich environment. All dryer ducting must maintain a minimum four-inch diameter with rigid metal construction for concealed portions, while flexible transition hoses must be aluminum or foil rather than plastic or vinyl materials that can melt or tear. The maximum allowable concealed duct length is thirty-five feet, with five feet deducted for every ninety-degree elbow and two and a half feet for every forty-five-degree fitting. When these specifications aren’t followed precisely, lint accumulation occurs much faster in humid climates, creating fire hazards while simultaneously forcing dryers to work harder and consume substantially more energy.

The economic impact of ventilation failures compounds over time through multiple damage mechanisms operating simultaneously. Inadequ

Recent Comments